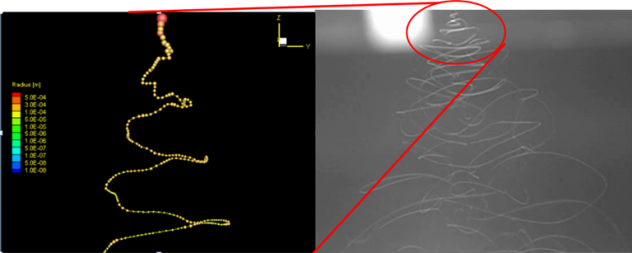

Fibers with diameters less than a micron can be formed using an electrospinning process where a droplet of a polymer solution is elongated by a strong electrical field, going over a vigorous whipping motion (see Fig. 1). The resulting nanofibers are collected as nonwoven mats with extremely large surface to volume ratios which are being used, or finding uses, in filtration, protective clothing, biomedical applications and reinforced composites. The electrospinning process also has advantages for investigation of fiber formation processes with new materials and solvents including the ability to work with small sample sizes, rapid time scale of the spinning/solvent removal process and high elongation of as spun fibers. We have been working on nanofibers formation of various advanced materials: i) inorganic nanofibers using electrospinning/sol-gel method, ii) polymer-inorganic nanocomposites, iii) metal and metal oxide nanofibers from water-based process. We would like to explore the possibility of tailoring the properties of these fibers on a nanoscale (~ 100 nm) via the electrospinning process. The group is also involved in continuum and mesoscale modeling of the fluid jet of the electrospinning process and the instability that the jet experiences while travelling to the collector.

Figure 1. Left: Discretized modeling of whipping motion during electrospinning by the group Right: High speed image of PVP/water jet during electrospinning

Selected Publications on Electrospun Nanofibers

- J. Li, C. Klaassen, P. Li, A. Kierulf, M. Yaghoobi, L. Khazdooz, A. Zarei, J. Smoot, Y.L. Joo, and A. Abbaspourrad, “Using gas-assisted electrospinning to design rod-shaped particles from starch for thickening agaents and Pickering emulsifiers”, Carbohydrate Polymers, 348, 122902 (2025).

- K.D. Kersey, H. Lee, J. Xu, M.K. Kidder, A.A. Park, and Y.L. Joo, “Encapsulation of Nanoparticle Organic Hybrid Materials within Electrospun Hydrophobic Polymer/Ceramic Fibers for Enhanced CO2 Capture”, Advanced Functional Materials 33, 2301649 (2023).

- S. Jin, Y. Shao, X. Gao, P. Chen, J. Zheng, J. Yin, Y.L. Joo, L.A. Archer “Designing interphases for practical aqueous Zinc flow battery with high power density and high areal capacity”, Science Advances 8, eabq4456 (2022).

- S. Sarkar, J.S. Won, M. An, R. Zhang, J.H. Lee, S.G. Lee and Y.L. Joo, “Tailoring Mesopores and Nitrogen Groups of Carbon Nano-fibers for Polysulfide Entrapment in Lithium-Sulfur Batteries”, Polymers 14, 1342 (2022).

- B.P. Williams, G.L. Shebert, and Y.L. Joo, “Metal Oxide Coatings on Carbon Electrodes with Large Mesopores for Deeply Charged Zinc Bromine Redox Flow Batteries”, Journal of Electrochemical Society 166, A2245-A2254 (2019).

- Y. Zhmayev, G.L. Shebert, S. Pinge, P. Kaur, H. Liu, and Y.L. Joo, “Non-Enthalpic Enhancement of Spatial Distribution and Orientation of CNTs and GNRs in Polymer Nanofibers”, Polymer 178, 121551 (2019).

- G. Shoorideh, B. Ko, A. Berry, M.J. Divvela, Y.K. Kim, Z. Li, B. Patel, S. Chakrapani, and Y.L. Joo, “Harvesting Inter and Intra-Conductivity of Graphene Nanoribbons for Directly Deposited, High-Rate Silicon-Based Anode for Li-ion Batteries”, ACS Applied Energy Materials 1, 1106-1115 (2018).

- J. Lee, B. Ko, J. Kang, Y. Chung, Y. Kim, W. Halim, J.H. Lee, and Y.L. Joo, “Facile and Scalable Fabrication of Highly Loaded Sulfur Cathodes and Lithium-Sulfur Pouch Cells via Air-Controlled Electrospray”, Materials Today Energy 6, 255–263 (2017).

- L. M. Shephard, M.W. Frey, and Y.L. Joo, “Immersion Electrospinning as a New Method to Direct Fiber Deposition”, Macromolecular Materials and Engineering 302 1700148 (2017).

- J.H. Park, and Y.L. Joo, “A Facile Precursor Route to Highly Loaded Metal/Ceramic Nanofibers as a Robust Surface-Enhanced Raman Template”, Applied Surface Science 416 742-750 (2017).

- S.A. Smith, B.P. Williams, and Y.L. Joo, “Effect of Polymer and Ceramic Morphology on the Material and Electrochemical Properties of Electrospun PAN/Polymer Derived Ceramic Composite Nanofiber Membranes for Lithium Ion Battery Separators”, Journal of Membrane Science 526, 315-322 (2017).

- S.A. Smith, J.H. Park, B.P. Williams, and Y.L. Joo, “Polymer/Ceramic Co-continuous Nanofiber Membranes via Room-Temperature Curable Organopolysilazane for Improved Lithium Ion Battery Performance”, Special Issue on Batteries and Supercapacitors, Journal of Materials Science 52, 3657-3669 (2017).

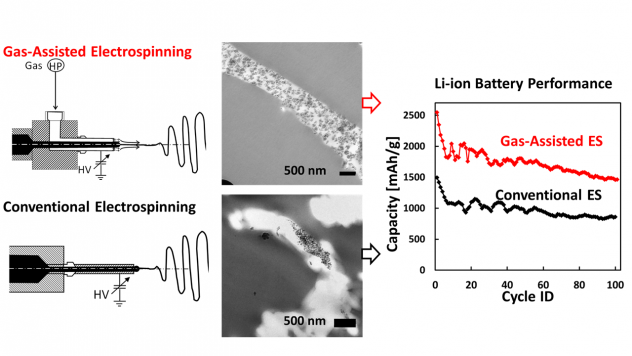

- Y. Zhmayev, S. Pinge, G. Shoorideh, G.L. Shebert, P. Kaur, H. Liu, and Y.L. Joo, “Controlling Placement of Spherical Nanoparticles in Electrically Driven Polymer Jets and Its Application to Li-ion Battery Anode”, Small 12, 5543–5553 (2016).

- G. Shoorideh, Y.S. Kim, and Y.L. Joo, “Facile, Water-Based, Direct-Deposit Fabrication of Hybrid Silicon Assemblies for Scalable and High-Performance Li-ion Battery Anodes”, Electrochimica Acta 222, 946-955 (2016).

- B.P. Williams, and Y.L. Joo, “Tunable Large Mesopores in Carbon Nanofiber Interlayers for High-Rate Lithium Sulfur Batteries”, Journal of The Electrochemical Society 163, A2745-A2756 (2016).

- L. Fei, B.P. Williams, S.H. Yoo, J. Kim, G. Shoorideh, and Y.L. Joo, “Graphene Folding in Si Rich Carbon Nanofibers for Highly Stable, High Capacity Li-Ion Battery Anodes”, ACS Applied Materials and Interfaces 8, 5243-5250 (2016).

- L. Fei, B.P. Williams, S.H. Yoo, J.M. Carlin, and Y.L. Joo, “A General Approach to Fabricate Free-standing Metal Sulfides@Carbon Nanofiber Network as Lithium Ion Battery Anodes”, Chemical Communication 52, 1501-1504 (2016).

- Y.S. Kim, G. Shoorideh, Y. Zhamyev, J.H. Lee, Z. Li, B. Patel, S. Chakrapani, J.H. Park, S. Lee, and Y.L. Joo, “Critical Contribution of Unzipped Graphene Nanoribbons to Stable Silicon Rich–Carbon Fiber Anodes for Rechargeable Li–ion Batteries”, Nano Energy 16, 446-457 (2015).

- J. Yin, J.M. Carlin, J. Kim, Z. Li, J.H. Park, B. Patel, S. Chakrapani, S. Lee, and Y.L. Joo, “Synergy between Metal Oxide Nanofibers and Graphene Nanoribbons for Rechargeable Lithium-Oxygen Battery Cathodes”, Advanced Energy Materials 5, 1401412 (2015).

- D. Cho, J.H. Park, Y. Jeong, and Y.L. Joo, “Synthesis of Titanium Carbide-Carbon Nanofibers via Carbothermal Reduction of Titania wih Carbon”, Ceramics International 41, 10974 (2015).

- D. Cho, M. Kim, J. Hwang, J.H. Park, Y.L. Joo, and Y. Jeong, “Facile Synthesis of Porous Silicon Nanofibers by Magnesium Reduction for Application in Lithium Ion Batteries”, Nanoscale Research Letters 10, 424 (2015).

- D. Cho, S. Chen, Y. Jeong, and Y.L. Joo, “Surface Hydro-properties of Electrospun Fiber Mats”, Fibers and Polymers 16, 1578-1586 (2015).

- Y.S. Kim, W.B. Kim, and Y.L. Joo, “Further Improvement of Battery Performance via Charge Transfer Enhanced by Solution-Based Antimony Doping into Tin Dioxide Nanofibers”, Journal of Materials Chemistry A 2, 2833-2837 (2014).

- J.H. Park, and Y.L. Joo, “Tailoring Nanorod Alignment in a Polymer Matrix by Elongational Flow under Confinement: Simulation, Experiments and Surface Enhanced Raman Scattering Application”, Soft Matter 10, 3494-3505 (2014).

- Y.S. Kim, K.W. Kim, D. Cho, N.S. Hansen, J. Lee, and Y.L. Joo, “Silicon-Rich Carbon Hybrid Nanofibers from Water-Based Spinning: The Synergy Between Silicon and Carbon for Li-ion Battery Anode Application”, ChemElectroChem 1, 220-226 (2014).

- D. Cho, A. Naydich, M.W. Frey and Y.L. Joo, “Further Improvement of Filtration Efficiency of Cellulose Filters Coated with Nanofibers via Inclusion of Electrostatically Active Nanoparticles”, Polymer 54, 2364-2372 (2013).

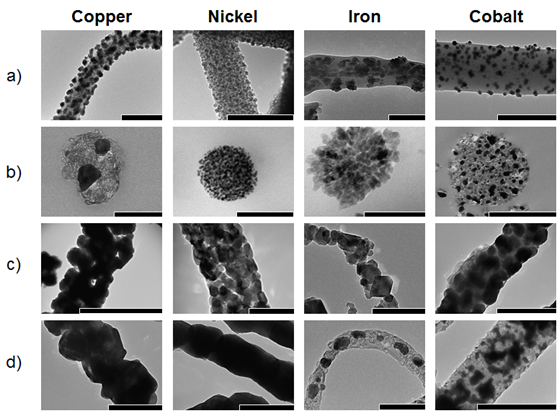

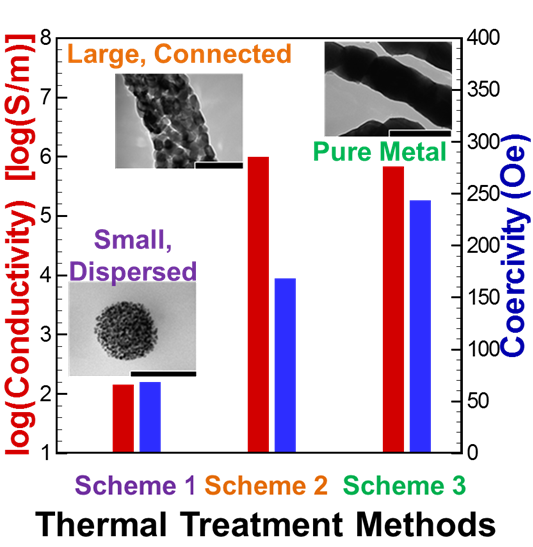

- N.S. Hansen, D. Cho, and Y.L. Joo, “Metal Nanofibers with Highly Tunable Electrical and Magnetic Properties via Highly Loaded Waster Based Electrospinning”, Small 8, 1510-1514 (2012).

- Y. Cho, D. Cho, J.H. Park, M.W. Frey, C.K. Ober, and Y.L. Joo, “Preparation and Characterization of Amphiphilic Triblock Terpolymer-Based Nanofibers as Antifouling Biomaterials”, Biomacromolecules 13, 1606-1614 (2012).

- D. Cho, A. Netravali, and Y.L. Jpp, “Mechanical Properties and Biodegradability of Electrospun Soy Protein Isolate/PVA Nanofibers”, Polymer Degradation and Stability 97, 747-754 (2012).

- N.S. Hansen, T.E. Furguson, J.E. Panels, A.A. Park and Y.L. Joo, “Inorganic Nanofibers with Tailored Placement of Nanocatalysts for the Hydrogen Production via Alkaline Hydrolysis of Glucose”, Nanotechnology 22, 325302 (2011).

- D. Cho, H. Zhou, and Y.L. Joo, “Structural Studies of Electrospun Nylon 6 Fibers from Solution and Melt”, Polymer 52, 4600-4609 (2011).

- D. Cho, H. Zhou, Y. Cho, D. Audus, and Y.L. Joo, “Structural Studies and Hydrophobicity of Electrospun Polypropylene Fibers from Solution and Melt”, Polymer 51, 6005-6012 (2010).

- M. Kamperman, L.T.J. Korley, B. Yau, K.M. Johansen, Y.L. Joo, U. Wiesner, “Nanomanufacturing of Continuous Composite Nanofibers with Confinement-induced Morphologies”, Polymer Chemistry 1, 1001-1004 (2010).

- V. Kalra, J.H. Lee, J. Park, M. Marquez and Y.L. Joo, “Confined Assembly of Asymmetric Block Copolymer Nanofibers via Multi-axial Jet Electrospinning”, Small 5, 2323-2332 (2009).

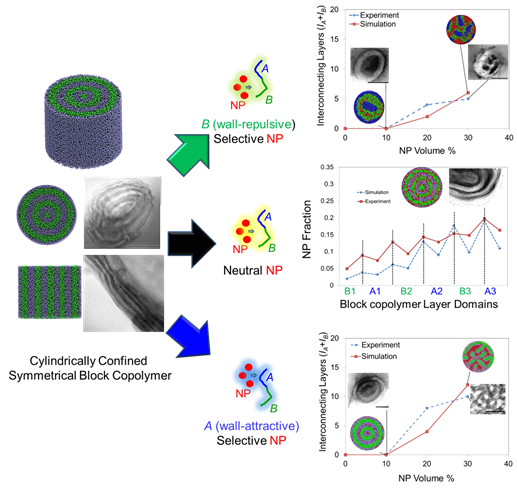

- V. Kalra, J. Lee, J.H. Lee, S.G. Lee, M. Marquez, U. Wiesner, Y.L. Joo, “Controlling Nanoparticle Location via Confined Assembly in Electrospun Block Copolymer Nanofibers”, Small 4, 2067-2073 (2008).

- J.E. Panels, J. Lee, K.Y. Park, S.Y. Kang, M. Marquez, U. Wiesner, Y.L. Joo, “Synthesis and Characterization of Magnetically Active Carbon Nanofiber/Iron Oxide Composites with Hierarchical Pore Structures”, Nanotechnology 19, 455612 (2008).

- H.J. Park, J.W. Dingee, S.R. Fitzgibbon, A.B. Anton, Y.L. Joo, “Controlling Cellulose Microstructure via Electrospinning with Applications in Enzymatic Hydrolysis”, Journal of Biobased Materials and Bioenergy 1, 245-256 (2007).

- V. Kalra, S. Mendez, J.H. Lee, H. Nguyen, M. Marquez, and Y.L. Joo, “Confined Assembly of Coaxially Electrospun Block Copolymer Fibers”, Advanced Materials 18, 3299-3303 (2006).

- V. Kalra, P.A. Kakad, S. Mendez, T. Ivannikov, M. Kamperman, and Y.L. Joo, “Self-Assembled Structures in Electrospun PS-b-PI Copolymers Fibers”, Macromolecules 39, 5453-5457 (2006).

- H. Zhou, T.B. Green, and Y.L. Joo, “The Thermal Effects on Electrospinning of Polylactic Acid Melts”,Polymer 47, 7497-7505 (2006).

- J.E. Panels and Y.L. Joo, “Incorporation of Vanadium Oxide in Silica Nanofiber Mats via Electrospinning and Sol-gel Synthesis”, Journal of Nanomaterials 2006, 41327 (2006).

- C.W. Kim, D.S. Kim, S.Y. Kang, M. Marquez and Y.L. Joo, “Structural Studies of Electrospun Cellulose Nanofibers”, Polymer, 47 5097-5107 (2006).

- H. Zhou, K.W. Kim, E.P. Giannelis, Y.L. Joo, “Nanofibers from Poly (L-Latic) Acid Nanocomposites: Effects of Nanoclay on Molecular Structures” in Polymeric Nanofibers, ACS Symposium Series Book 918, 217-230 (2006).

- C.W. Kim, M.W. Frey, M. Marquez and Y.L. Joo, “Preparation of Electrospun Cellulose Nanofibers via Direct Dissolution”, Journal of Polymer Science: Part B: Polymer Physics 43, 1673-1683 (2005).

- S.S. Choi, S.G. Lee, S.S. Im, S.H. Kim and Y.L. Joo, “Silica Nanofibers from Electrospinning/Sol-Gel Process”, Journal of Materials Science Letters 22, 891-893 (2003).

Publications on Nanofiber Modeling

- M.J. Divvela and Y.L. Joo, “Design Principles in Continuous Inkjet Electrohydrodynamic Printing from Discretized Modeling and Image Analysis”, Journal of Manufacturing Processes 54, 413-419 (2020).

- M.J. Divvela, L. M. Shephard, M.W. Frey, and Y.L. Joo, “Discretized Modeling of Motionless Printing based on Retarded Bending Motion and Deposition Control of Electrically Driven Jet”, 3D Printing and Additive Manufacturing 5, 248-256 (2018).

- M.J. Divvela, A.C. Ruo, Y. Zhmayev, and Y.L. Joo, “Discretized Modeling for Centrifugal Spinning of Viscoelastic Liquids”, J. of Non-Newtonian Fluid Mechanics 247, 62-77 (2017).

- M.J. Divvela and Y.L. Joo, “Discretized Modeling of Beads on a String Morphology from Conducting and Viscoelastic Polymer Jets during Electrospinning”, J. of Applied Physics 121, 134306 (2017).

- Y. Zhmayev, M.J. Divvela, A.C. Ruo, T. Huang, and Y.L. Joo, “The Jetting Behavior of Viscoelastic Boger Fluids during Centrifugal Spinning, Physics of Fluids 27, 123101 (2015).

- E. Zhmayev, D. Cho and Y.L. Joo, “Electrohydrodynamic Quenching in Polymer Melt Electrospinning”, Physics of Fluids 23, 073102 (2011).

- C.P. Carroll and Y.L. Joo, “Discretized Modelling of Electrically Driven Viscoelastic Jets in the Initial Stage of Electrospinning”, Journal of Applied Physics 109, 094315 (2011).

- E. Zhmayev, D. Cho and Y.L. Joo, “Nanofibers from Gas-Assisted Polymer Melt Electrospinning”, Polymer 51, 4140-4144 (2010).

- E. Zhmayev, D. Cho and Y.L. Joo, “Modeling of Melt Electrospinning for Semi-Crystalline Polymers”, Polymer 51, 274-290 (2010).

- C.P. Carroll and Y.L. Joo, “Axisymmetric Instabilities in Electrospinning of Highly Conducting, Viscoelastic Polymer Solutions”, Physics of Fluids 21, 103101 (2009).

- V. Kalra, J.H. Lee, J. Park, M. Marquez and Y.L. Joo, “Confined Assembly of Asymmetric Block Copolymer Nanofibers via Multi-axial Jet Electrospinning”, Small 5, 2323-2332 (2009).

- C.P. Carroll and Y.L. Joo, “Axisymmetric Instabilities of Electrically Driven Viscoelastic Jets”, Journal of Non-Newtonian Fluid Mechanics 153, 130-148 (2008).

- E. Zhmayev, H. Zhou and Y.L. Joo, “Modeling of Non-isothermal Polymer Jets in Melt Electrospinning”, Journal of Non-Newtonian Fluid Mechanics 153, 95-108 (2008).

- C.P. Carroll and Y.L. Joo, “Electrospinning of Viscoelastic Boger Fluids: Modeling and Experiments”, Physics of Fluids 18, 053102-14 (2006).