One of recent areas of our research is on graphene materials such as graphene nanoribborns (GNR), graphene oxide (GO), reduced graphene oxide (rGO) and few layer graphene (FLG). We synthesize structurally uniform graphenic materials and their assembly into fibers and films for light-weight composite applications and energy storage applications.

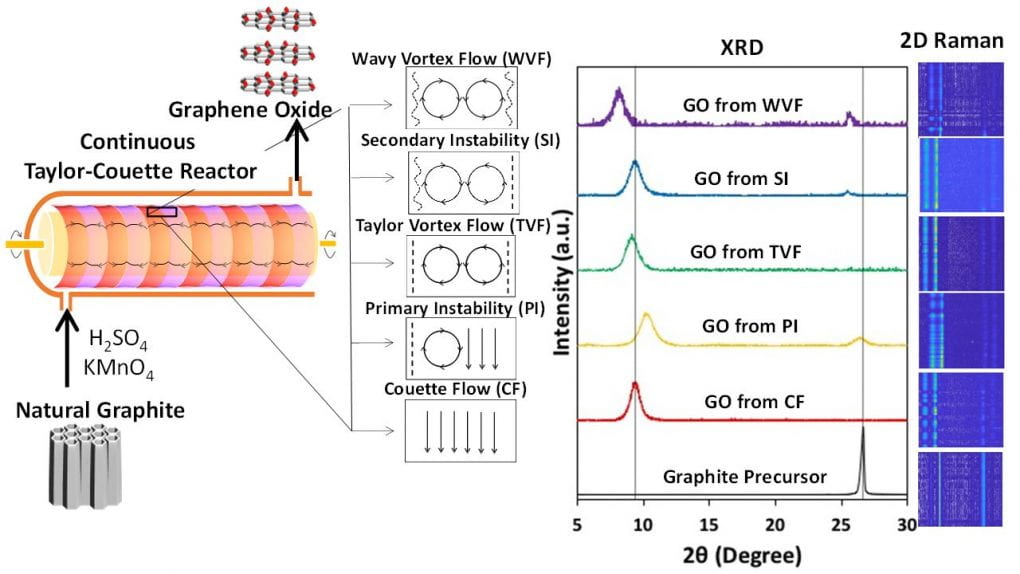

Continuous synthesis of structurally uniform graphene oxide materials in a model Taylor-Couette flow reactor

Graphene oxide (GO) has proven to be an invaluable material for a wide range of applications. The development of a bulk-scale continuous process to synthesize GO materials has become crucial. In this study, we used a model Taylor-Couette reactor with axial flow to transform the oxidation of graphite flakes into a continuous process. Efficient mixing of graphite and oxidizing agents were achieved via Taylor vortices, which remarkably shortened the duration of graphite oxide (GtO) synthesis from hours to minutes. Our results reveal that the level of oxidation increased at the Taylor Vortex Flow (TVF) regime and significantly decreased at other hydrodynamic flow regimes. More importantly, TVF regime resulted in structurally uniform GtO products. This confirms that the developed apparatus offers a robust method to synthesize high-quality, structurally uniform GtO in a continuous manner that can be used in numerous applications.

Fig. 1. Taylor-Couette reactor with axial flow was utilized to transform graphite into graphene oxide continuously. Efficient mixing and diffusion of graphite and oxidizing agents were achieved, which remarkably shortened GO synthesis from hours to minutes. Out of various flow structures investigated, Taylor Vortex Flow resulted in a structurally uniform GO product.

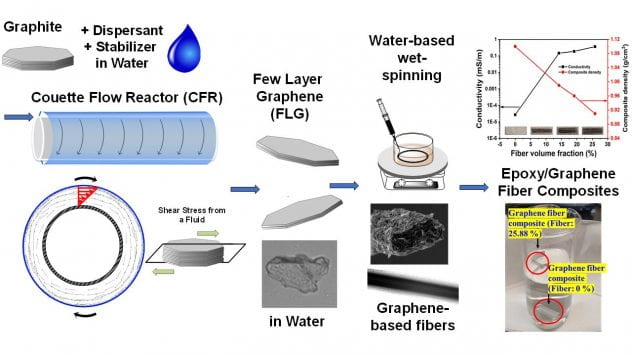

Graphene Exfoliation and Folding into Fibers via Water-Based, Surfactant-Aided Mechanical Deformations, and Their Application to Density-Controlled, High Performance Composites

Structurally uniform expanded graphite (EG) and few layer graphene (FLG) sheets with large lateral dimension (> 10 mm) have been obtained from aqueous solution of graphite flakes using a Taylor-Couette Reactor (TCR). The current facile, water-based, surfactant-aided approach utilizes laminar Couette flow structure and high shear rates via the rotation of the outer cylinder while the inner cylinder is still in a Taylor-Couette device, which dampens vortex formation due to the suppression of centrifugal forces. Our results reveal that the level of expansion and exfoliation using an aqueous solution and a Taylor-Couette reactor can be controlled via tailoring shearing time. The resulting mixture of EG and FLG has further been assembled and folded into graphene fibers via water-based wet-spinning, producing ultra-light fibers with bulk density of 0.35 g/cm3. These fibers exhibit an exceptional thermal and electrical conductivity of 2 x103 W/K-m and 2 x 105 S/m, respectively as well as impressive mechanical properties of ~0.5 GPa strength and 40 GPa Young’s modulus via entirely water based process, from achieving exfoliation of graphite through assembling into fibers. Furthermore, the resulting ultralight high performance graphene fibers have been incorporated into epoxy resin, producing self-floating, lightweight composites with enhanced electrical and mechanical properties, which offer a great potential in light-weight composite applications, replacing dense carbon, ceramic or steel fibers.

Fig. 2 Facile production of graphene microsheets and their assembly into light-weight fibers via water-based, surfactant-aided mechanical deformations, and their application to density-controlled, high performance composites

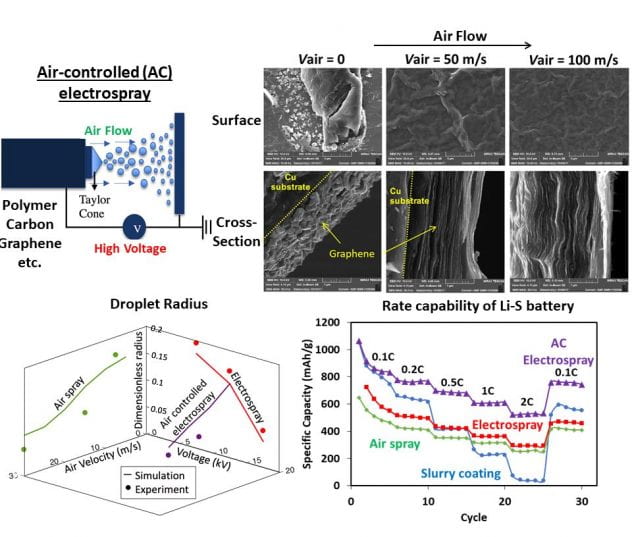

Direct deposition of graphenic materials into layered structure

We have been developing scalable processes where the assembly of nanomaterials such as graphene sheets can be tailored. These include air-controlled electrospray (ACE) where effective layering and flattening of graphene and graphene oxide sheets on a copper metal substrate has been demonstrated (see Figure 3). With increasing controlled air flow, the surface roughness and density of the deposited layers can also be controlled. ACE of graphene containing aqueous solution has successfully been applied to Li-ion and Li-Sulfur electrodes to tailor the assembly of graphene-silicon or graphene-sulfur hybrids.

Fig. 3 Effect of air flow on the layering of graphene oxide sheets on solid substrate via air-controlled electrospray, and improvement in reducing droplet sizes and enhancing Li-S battery performance especially at high rates

Related Publications

- V. Shah, R. Sinha, W. Cesarski, X. Gao, S. Yuk, and Y.L. Joo, “Modality-Tunable Exfoliated N-doped Graphene As Effective Electrolyte Additive for High-Performance Lithium-Sulfur Batteries”, ACS Applied Materials and Interfaces 16, 53950 (2024).

- M. Salim, V. Vasudevan, N. Schulman, S. Zamani, K.D. Kersey, Y. Joshi, M. AlAmer, J.I. Choi, S.S. Jang and Y.L. Joo, “Thermoresponsive Conductivity of Graphene-based Fibers”, Small 19, 2204981 (2023).

- S. Jin, Y. Shao, X. Gao, P. Chen, J. Zheng, J. Yin, Y.L. Joo, L.A. Archer “Designing interphases for practical aqueous Zinc flow battery with high power density and high areal capacity”, Science Advances 8, eabq4456 (2022).

- Y. Joshi, A. Umasankaran, C. Klaassen, M. AlAmer, and Y.L. Joo, “Critical Roles of Reduced Graphene Oxide in the Electrochemical Performance of Silicon/Reduced Graphene Oxide Hybrids for High Rate Capable Lithium-ion Battery Anodes”, Electrochimca Acta 404, 139753 (2022).

- Y. Joshi, S. Zamani, C. Klaassen, and Y.L. Joo,” Mitigation and In-situ Probing of Volume Expansion in Silicon Graphene Hybrid Anodes for High Capacity, High Rate Capable Lithium Ion Batteries”, Advanced Energy and Sustainable Research 2, 2100125 (2021).

- C-W. Chang, S. Zamani, H. Seo, Y. Park, T. Kang, D.M. Smilgies, A.R. Lim, and Y.L. Joo, “A Prospect of Cost-Effective Handling and Transportation of Graphene Oxides: Folding and Redispersion of Graphene Oxide Microsheets”, Nanotechnology 32, 455601 (2021).

- S. Zamani, J.S Won, M. Salim, M. AlAmer, C.W. Chang, P. Kumar, K. Amponsah, A.R. Lim, and Y.L. Joo, “Ultralight Graphene/Graphite Hybrid Fibers via Entirely Water-based Processes and Their Application to Density-controlled, High Performance Composites”, Carbon 173, 880–890 (2021).

- M. AlAmer, S. Zamani, K. Fok, A. Satish, A.R. Lim and Y.L. Joo, “Facile Production of Graphenic Microsheets and Their Assembly via Water-based, Surfactant-aided Mechanical Deformations”, ACS Applied Materials and Interfaces 12, 8944-8951 (2020).

- M.J. Divvela, R. Zhang, Y. Zhmayev, S. Pinge, J.H. Lee, S.W. Kim and Y.L. Joo, “Control of Formation of Viscoelastic Droplets and Distribution of Nano-inclusions in Functional Deposition for Lithium-Sulfur Batteries”, Soft Matter 15, 6485-6494 (2019).

- Y. Zhmayev, G.L. Shebert, S. Pinge, P. Kaur, H. Liu, and Y.L. Joo, “Non-Enthalpic Enhancement of Spatial Distribution and Orientation of CNTs and GNRs in Polymer Nanofibers”, Polymer 178, 121551 (2019).

- M. AlAmer, A.R. Lim, and Y.L. Joo, “Continuous Synthesis of Structurally Uniform Graphene Oxide Materials in a Model Taylor-Couette Flow Reactor”, Ind. Eng. Chem. Res. 58, 1123-1462 (2019).

- W. Halim, J.H. Lee, S.M. Park, R. Zhang, S. Sarkar, T. O’Neil, E. Chiang, and Y.L. Joo, “Directly Deposited Binder Free Sulfur Electrode Enabled by Air-Controlled Electrospray Process”, ACS Applied Energy Materials 2, 678−686 (2019).

- J.H. Lee, J. Kang, S.W. Kim, W. Halim, M.W. Frey, and Y.L. Joo, “Effective Suppression of the Polysulfide Shuttle Effect in Lithium–Sulfur Batteries by Implementing rGO-PEDOT:PSS Coated Separators via Air-Controlled Electrospray”, ACS Omega 3 16465–16471 (2018).

- G. Shoorideh, B. Ko, A. Berry, M.J. Divvela, Y.K. Kim, Z. Li, B. Patel, S. Chakrapani, and Y.L. Joo, “Harvesting Inter and Intra-Conductivity of Graphene Nanoribbons for Directly Deposited, High-Rate Silicon-Based Anode for Li-ion Batteries”, ACS Applied Energy Materials 1, 1106-1115 (2018).

- L. Fei, S.H. Yoo, R.A. Villamayor, B.P. Williams, S. Gong, S. Park, K. Shin, and Y.L. Joo, “Graphene Oxide Involved Air-controlled Electrospray for Uniform, Fast, Instantly Dry, and Binder-Free Electrode Fabrication”, ACS Applied Materials & Interfaces 9, 9738–9746 (2017).

- G. Shoorideh, Y.S. Kim, and Y.L. Joo, “Facile, Water-Based, Direct-Deposit Fabrication of Hybrid Silicon Assemblies for Scalable and High-Performance Li-ion Battery Anodes”, Electrochimica Acta 222, 946-955 (2016).

- J. Kim, J.M Carlin, S.A. Smith and Y.L. Joo, “Thermal Restacking of Graphene Structure to Improve Lithium-air Battery Cyclability”, Electrochem. Communication 70, 43-46 (2016).

- L. Fei, B.P. Williams, S.H. Yoo, J. Kim, G. Shoorideh, and Y.L. Joo, “Graphene Folding in Si Rich Carbon Nanofibers for Highly Stable, High Capacity Li-Ion Battery Anodes”, ACS Applied Materials and Interfaces 8, 5243-5250 (2016).

- Y.S. Kim, G. Shoorideh, Y. Zhamyev, J.H. Lee, Z. Li, B. Patel, S. Chakrapani, J.H. Park, S. Lee, and Y.L. Joo, “Critical Contribution of Unzipped Graphene Nanoribbons to Stable Silicon Rich–Carbon Fiber Anodes for Rechargeable Li–ion Batteries”, Nano Energy 16, 446-457 (2015).

- J. Yin, J.M. Carlin, J. Kim, Z. Li, J.H. Park, B. Patel, S. Chakrapani, S. Lee, and Y.L. Joo, “Synergy between Metal Oxide Nanofibers and Graphene Nanoribbons for Rechargeable Lithium-Oxygen Battery Cathodes”, Advanced Energy Materials 5, 1401412 (2015).