We are developing structural and molecular models which are of great importance in interrelating the microstructure with processing conditions, and numerical methods to couple efficiently simulation of the macroscopic flow with evolution of the underlying molecular configurations over many different time and length scales. The dynamics of complex polymer systems such as block copolymer/nanoparticle composites, polymer blends, micelles or branched polymers under shear and elongation flows have been investigated by using Coarse-Grained Molecular Dynamics or Brownian dynamics simulations. We also systematically incorporate the physical insight into a new, coarser-scale model for polymers. The new model captures the finer scale physics of the polymer chain model in a wide range of flows, but it is sufficiently simple to be used in the analysis of flows in complex geometries. The efficient, parallel, time integration scheme is effectively utilized when even more complicated constitutive descriptions such as molecular models for liquid crystalline polymers, multi-mode models, and multi-phase models are required in complex viscoelastic flow simulations. The crystallization kinetics including stress-induced crystallization also are incorporated into the simulation of various polymer processing operations such as fiber spinning, film casting, film blowing, and injection molding to obtain favorable comparisons between experimental data and numerical simulations. Finally, coarse-grained molecular dynamics (CGMD) modeling has been applied to the block copolymer lithography and three dimensional line edge roughness has been analyzed before and after the wet or dry etching process.

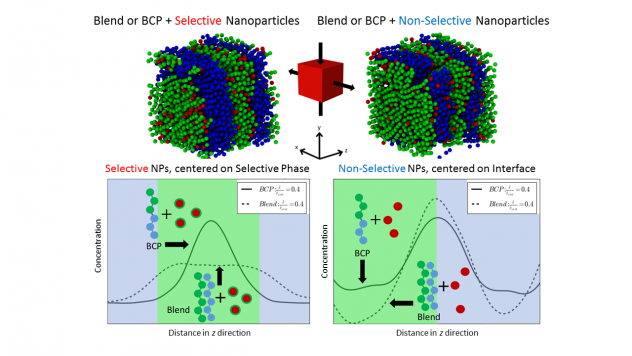

Fig 1. The interplay between NPs and polymer blend under elongational flow leads to interesting morphology of nanocompsoites that can significantly impact the utilization of nanostructures in various applications by offering the control the placement of nanoparticles in polymer blends.

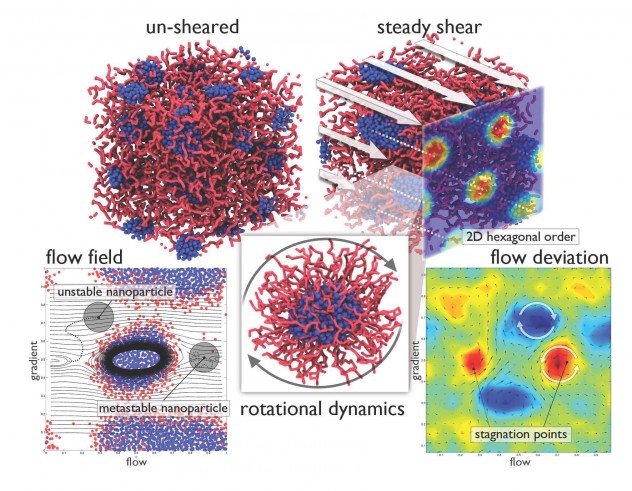

Fig. 2. Ordering of polymeric micelles can be enhanced via shear flow and resulting polymeric micelles can template nanoparticles via interstitial sites in shear-ordered micelle solutions.

Fig. 3 Coarse-graining of polymers and molecular dynamics simulations under shear and elongational flow.

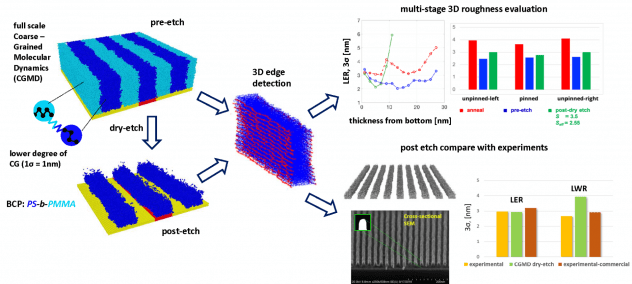

Fig. 4 Mesoscale modeling of 3D Line Edge Roughness of pre and post etched line and space patterns in block copolymer lithography

Related Publications

- S. Sham Sunder Bharadwaj, M.J. Divvela, and Y.L. Joo, “Facile Adaptation of a Fused Deposition Modeling 3D Printer to Motionless 3D Printing via Programmable Electric Relay: Discretized Modeling and Experiments”, 3D Printing and Additive Manufacturing 11, 251 (2024).

- M. Salim, V. Vasudevan, N. Schulman, S. Zamani, K.D. Kersey, Y. Joshi, M. AlAmer, J.I. Choi, S.S. Jang and Y.L. Joo, “Thermoresponsive Conductivity of Graphene-based Fibers”, Small 19, 2204981(2023).

- M.J. Divvela and Y.L. Joo, “Design Principles in Continuous Inkjet Electrohydrodynamic Printing from Discretized Modeling and Image Analysis”, Journal of Manufacturing Processes 54, 413-419 (2020).

- S. Pinge, Y. Qiu, V. Monreal, D. Baskaran, A. Ravirajan. and Y.L. Joo, “Comprehensive Analysis of Three-Dimensional Line Edge Roughness in Pre-and Post- Dry Etch Line Space Patterns of Block Copolymer Lithography”, Physical Chemistry Chemical Physics 22, 478 – 488 (2020).

- M.J. Divvela, R. Zhang, Y. Zhmayev, S. Pinge, J.H. Lee, S.W. Kim and Y.L. Joo, “Control of Formation of Viscoelastic Droplets and Distribution of Nano-inclusions in Functional Deposition for Lithium-Sulfur Batteries”, Soft Matter 15, 6485-6494 (2019).

- M.J. Divvela, L. M. Shephard, M.W. Frey, and Y.L. Joo, “Discretized Modeling of Motionless Printing based on Retarded Bending Motion and Deposition Control of Electrically Driven Jet”, 3D Printing and Additive Manufacturing 5, 248-256 (2018).

- S. Pinge, D. Baskaran, Y.L. Joo, “Evaluation of Line-edge/ Line-width Roughness of Directed Self-assembled PS-b-PMMA patterns using Coarse-Grained Molecular Dynamics Simulation”, SPIE Proceedings 10584N, Emerging Patterning Technologies (2018).

- G.L. Shebert and Y.L. Joo, “Simultaneous Uniaxial Extensional Deformation and Cylindrical Confinement of Block Copolymers using Non-equilibrium Molecular Dynamics”, Soft Matter 14, 1389-1396 (2018).

- S. Pinge, G. Lin, D. Baskaran, M. Padmanaban, and Y.L. Joo, “Designing an Ordered Template of Cylindrical Arrays based on a Simple Flat Plate Confinement of Block Copolymers: A Coarse-Grained Molecular Dynamics Study”, Soft Matter 14, 597-613 (2018).

- M.J. Divvela, A.C. Ruo, Y. Zhmayev, and Y.L. Joo, “Discretized Modeling for Centrifugal Spinning of Viscoelastic Liquids”, J. of Non-Newtonian Fluid Mechanics 247, 62-77(2017).

- M.J. Divvela and Y.L. Joo, “Discretized Modeling of Beads on a String Morphology from Conducting and Viscoelastic Polymer Jets during Electrospinning”, J. of Applied Physics 121, 134306 (2017).

- G.L. Shebert and Y.L. Joo, “Effect of Elongational Flow on Immiscible Polymer Blend/Nanoparticle Composites: a Molecular Dynamics Study”, Soft Matter 12, 6132-6140 (2016).

- B.P. Williams, S. Pinge, Y.K. Kim, J. Kim, and Y.L. Joo, “Enhanced Dispersion and Stability of Petroleum Coke Water Slurries by Triblock Copolymer and Xanthan Gum: Rheological and Adsorption Studies”, Langmuir 31, 8989-8997 (2015).

- J.H. Park, J. Yin, V. Kalra, and Y.L. Joo, “Role of Nanoparticle Selectivity in the Symmetry Breaking of Cylindrically Confined Block Copolymers”, Journal of Physical Chemistry C 118, 7653-7668 (2014).

- J.H. Park, and Y.L. Joo, “Interconnected Morphologies via Nanorod Inclusion in Confined Assembly of Symmetric Block Copolymers”, Physical Chemistry Chemical Physics 16, 8865-8871 (2014).

- J.H. Park and Y.L. Joo, “Tailoring Nanorod Alignment in a Polymer Matrix by Elongational Flow under Confinement: Simulation, Experiments, and Surface Enhanced Raman Scattering Application”, Soft Matter 10, 3494-3505 (2014).

- J.H. Park, V. Kalra, and Y.L. Joo, “Controlling the Dispersion and Orientation of Nanorods in Polymer Melt under Shear: Coarse-Grained Molecular Dynamics Simulation Study”, Journal of Chemical Physics 140, 124903 (2014).

- B.A. Rolfe, J. Chun, Y.L. Joo, “Dynamics of Micelle-Nanoparticle Systems Undergoing Shear: A Coarse-Grained Molecular Dynamics Approach”, Soft Matter 9, 10294-10305 (2013).

- J.H. Park, V. Kalra, Y.L. Joo, “Cylindrically Confined Assembly of Asymmetrical Block Copolymers with and without Nanoparticles”, Soft Matter 8, 1845-1857 (2012).

- C.P. Carroll and Y.L. Joo, “Discretized Modelling of Electrically Driven Viscoelastic Jets in the Initial Stage of Electrospinning”, Journal of Applied Physics 109, 094315 (2011).

- V. Kalra, F. Escobedo, Y.L. Joo, “Effect of Shear on Nanoparticle Dispersion in Polymer Melts: A Coarse-grained Molecular Dynamics Study”, Journal of Chemical Physics 132, 024901 (2010).

- V. Kalra, Y.L. Joo, “Coarse-Grained Molecular Dynamics Study of Block Copolymer/Nanoparticle Composites under Elongational Flow”, Journal of Chemical Physics 131, 214904 (2009).

- V. Kalra, S. Mendez, F. Escobedo, Y.L. Joo, “Coarse-grained Molecular Dynamics Simulation on the Placement of Nanoparticles within Symmetric Diblock Copolymers under Shear Flow”, Journal of Chemical Physics, 128, 164909 (2008).

- Y.M. Lee and Y.L. Joo, “Brownian Dynamics Simulations of Polyelectrolyte Molecules Traveling through an Entropic Trap Array during Electrophoresis”, Journal of Chemical Physics, 127, 124902 (2007).

- Y.M. Lee and Y.L. Joo, “Brownian Dynamics Simulations of Star-Branched Polymers in Dilute Solutions in Extensional Flow”, Journal of Non-Newtonian Fluid Mechanics, 140, 71-86 (2006).